Metal Products

nail

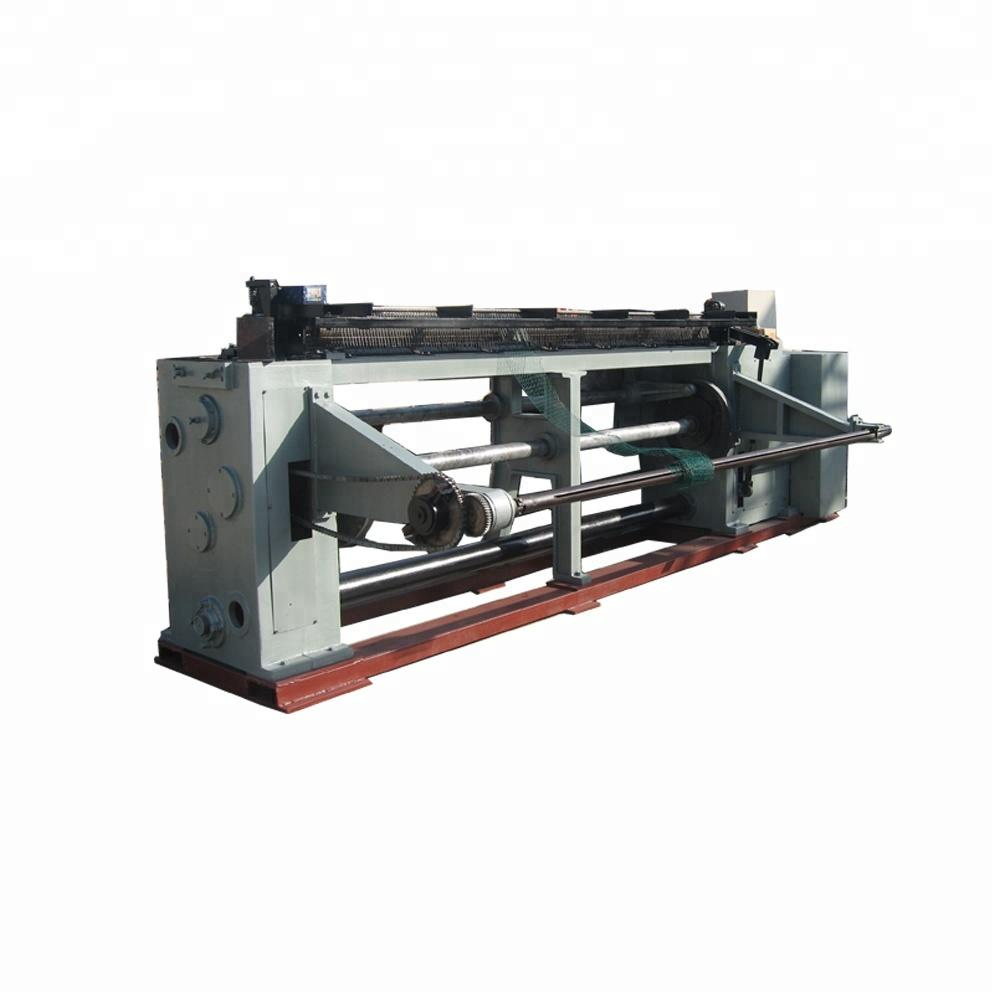

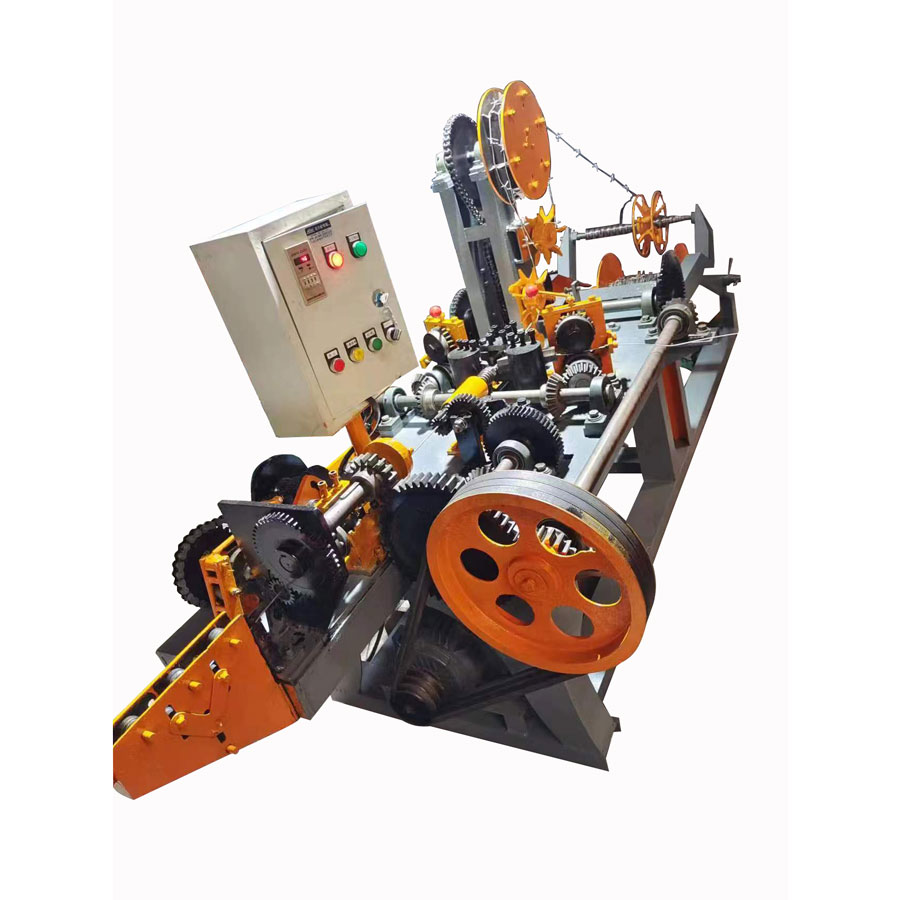

The production process mainly includes wire drawing, cold heading, polishing and other processes, while the production process of nails is relatively simple. Nails are produced by special machines.

The raw material for the production of nails is a round steel plate, which is formed into a round steel plate. After wire drawing, the diameter of the nail rod is pulled out, and then cold heading is carried out to make the tail and tip of the nail, and then polishing treatment is carried out to obtain the finished product. If the surface of the nail needs to be electroplated or blackened, these processes can also be added.

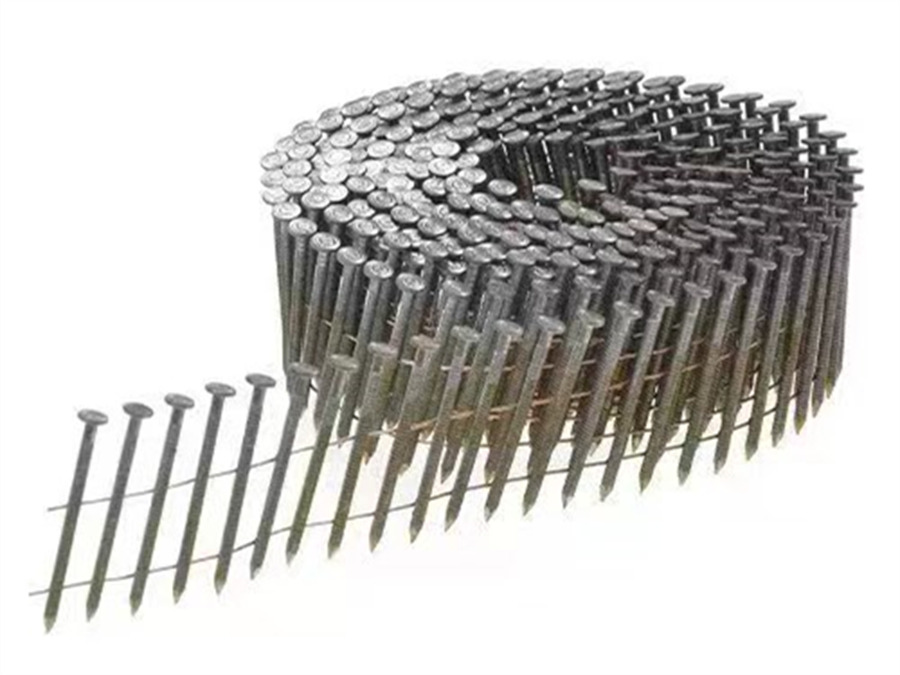

Types, steel row nails, cement steel nails, wood screws, self tapping screws, shooting nails, straight nails, various nails

features

Nails are made by feeding a thick, continuous steel wire into a machine where the wire is gripped between two dies and is cut to the desired length. Sufficient metal to form the head is allowed to protrude from the dies at one end and is then flattened into a head by a blow from a mechanized hammer. The other end of the piece of wire is cut into a point, after which the nail is ejected from the machine and may be smoothed (to remove the rough edges), polished, or plated.

Nails are made of steel wire as raw material and processed by nail making machine. Suitable for burying nail heads into wood for floor nails, furniture nails, wood mold nails, etc.

1. Flat-head nails are often used for nailing construction projects and packaging boxes. They have a large flat head and are easy to pull out when nailed into wood.

2. Corrugated nails, the surface is galvanized and passivated, bright in color, and rust-free. The nail head and nail body are riveted. They are mainly used to fix the tail tiles.

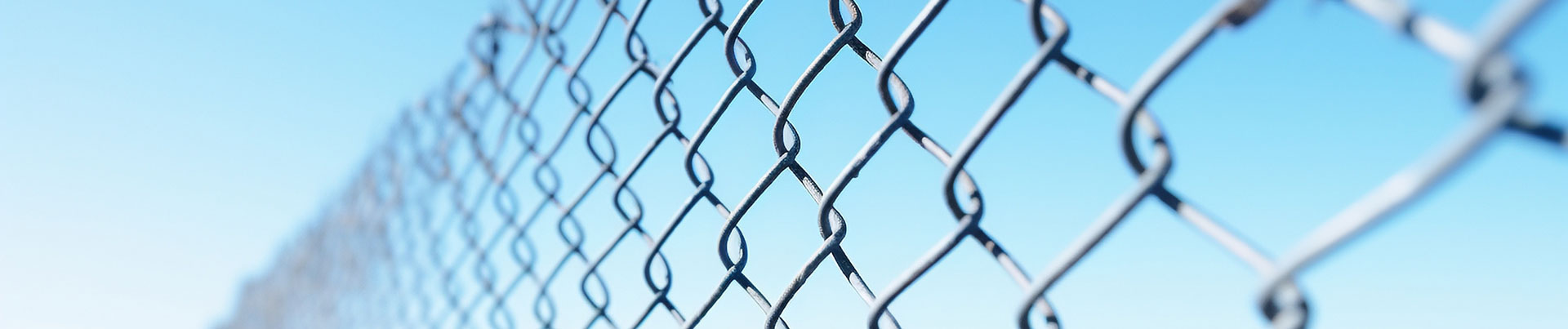

3. Horse-riding nails are used to fix metal mesh, barbed wire, structural frames, etc.

4. Triangular nails are a type of special-shaped nails with a triangle-shaped nail shaft, commonly known as fishtail nails. They are mainly used for fixing structures such as sofas and farm tools.

4. Square nails, the nail shaft is square, and they are mainly used to nail objects that are not easy to rotate after being stressed, such as for repairing wooden boats and building bridges.

5. Cement nails are used for nailing into cement components and cement brick walls. They are made of medium and high-carbon high-quality carbon structural steel and have high strength and hardness.