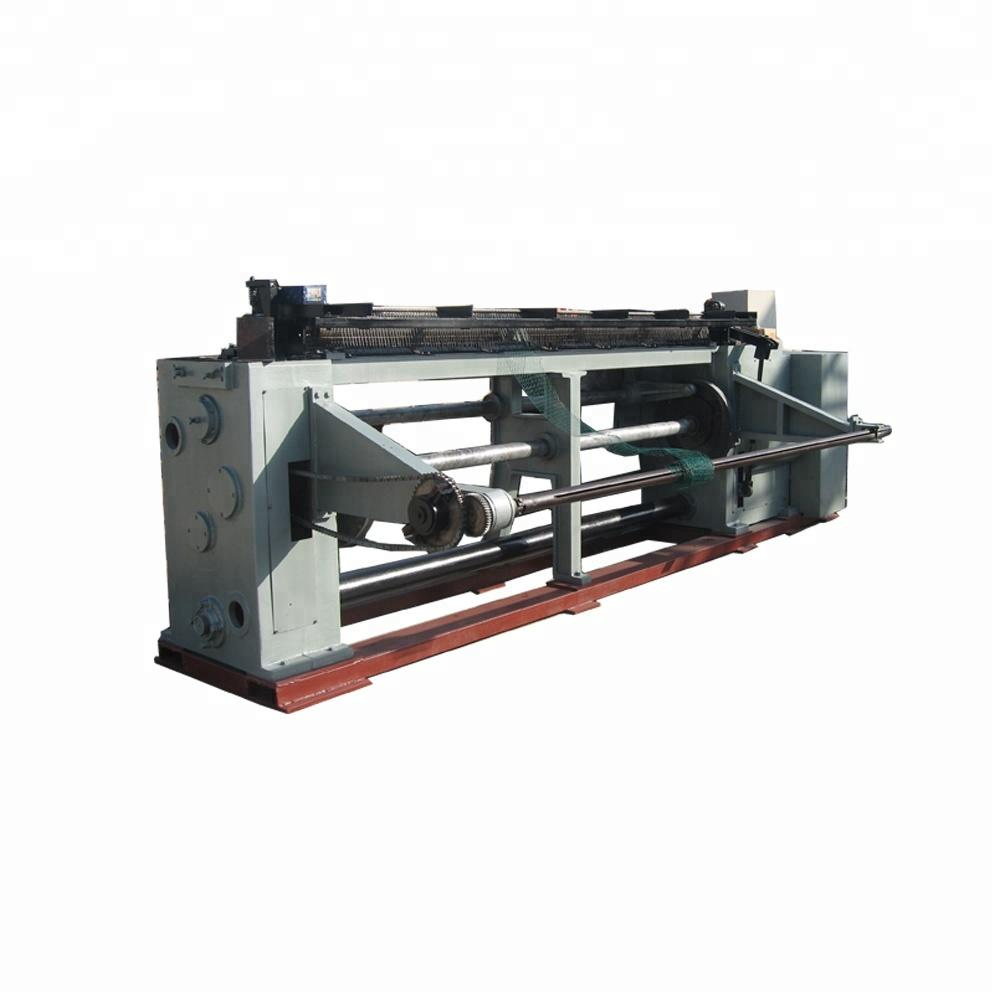

Refractory Material Bulk Bag Filling SystemsTonne Bag Filler For 500kg To 1200kg

Application

Solid: candy, peanut, green bean, pistachio, brown sugar, cake, daily commodities, cooked food, pickles, puffed food etc.

Granule: grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts etc.

Powder: milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc.

Working Flow

a). Manual hang ton bag on the mounting ear.

b). Manual press start button.

c). The products will free fall in the ton bag and detected by the load cell, when reach target weight, filling stop.

d). Manual take the bag down.

e). Electric trolly moves on the track back and forth and conveys packed products

technical parameters

Contact parts |

SUS304 |

Machine frame |

Carbon steel with paint |

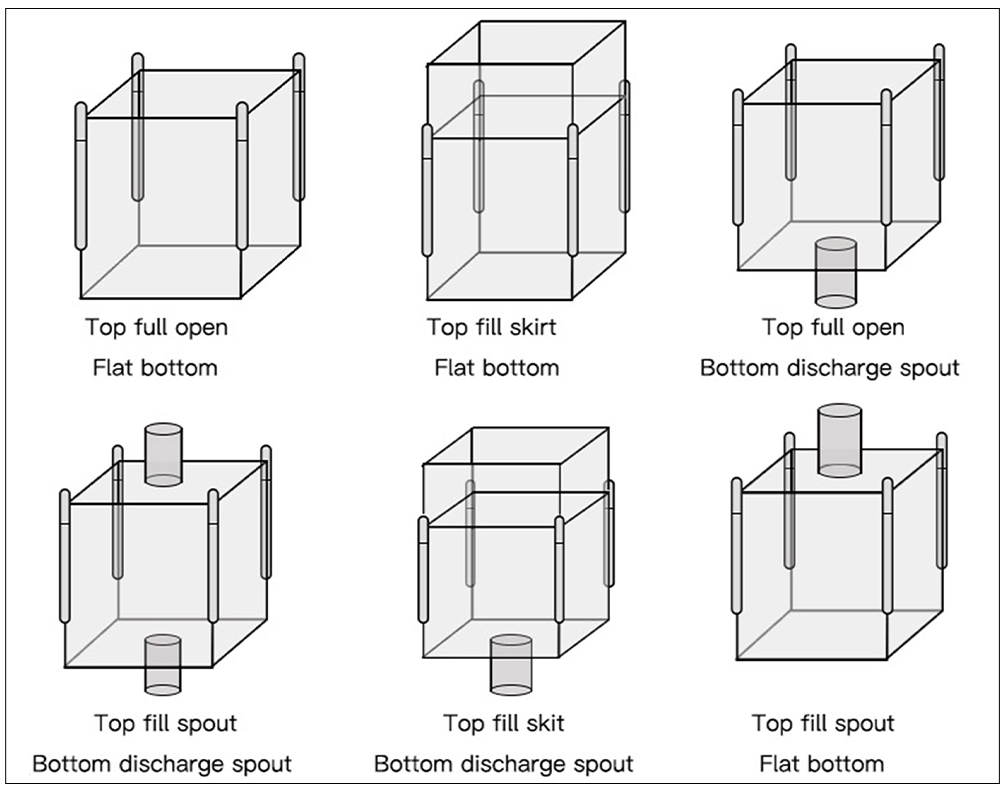

Packing Form |

Bulk bag |

Packing weight |

500~1200kg |

Accuracy |

±0.2% |

Air Supply |

0.4-0.6Mpa |

Air Consumption |

2m3/hour |

Powder supply |

AC380V,3P,50HZ,3KW |

External dimension |

L5200xW1800XH3500mm |

Configuration List

|

NO |

PRODUCT |

BRAND |

QTY |

|

1 |

Weighing control part: (1) Stainless steel scale (2) Stainless steel sensor (3) Stainless steel junction box (4) Weighing operating instrument (5) Erecting by overhang (6) Hanging cylinder (7) Electric control cabinet |

USA Mettler Toledo LEADALL PACK LEADALL PACK LEADALL PACK LEADALL PACK SMC LEADALL PACK |

1 4 1 1 1 4 1 |

|

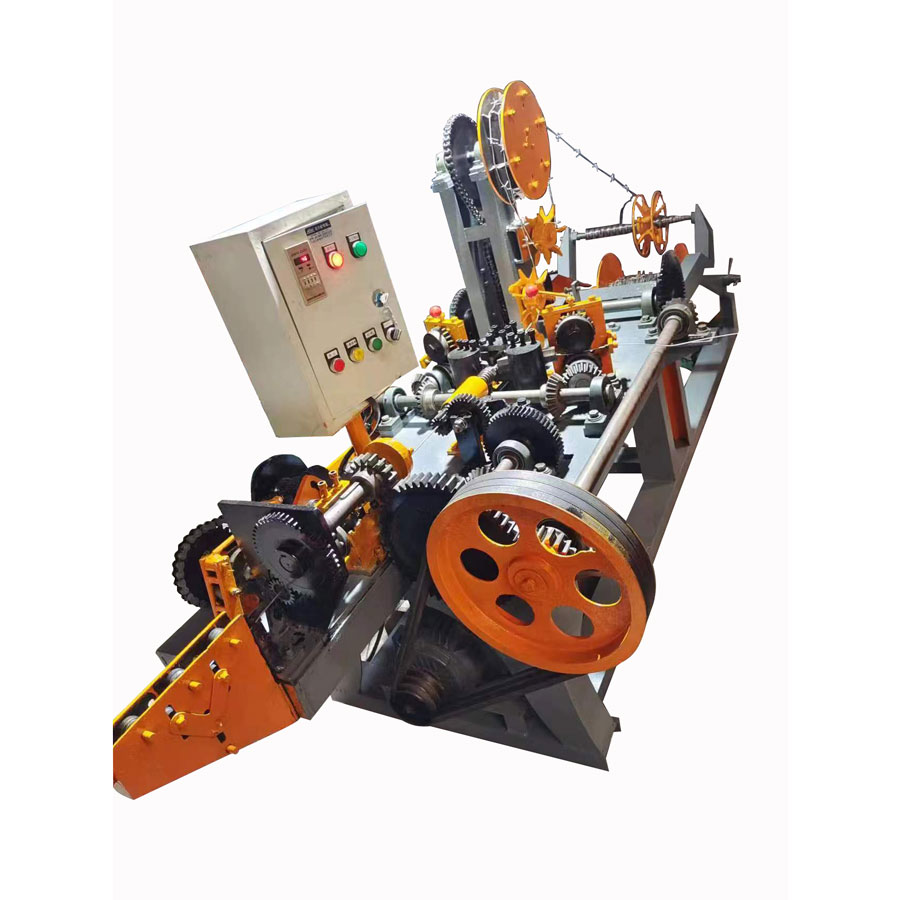

2 |

Feeding control part: (1) Feed solenoid pilot actuated valve (2) Feed cylinder (3) Stainless feed door (4) Bag-clamped solenoid pilot actuated valve (5) Bag-clamped cylinder (6) Bag-clamped part (7)PLC |

SMC SMC LEADALL PACK LEADALL PACK SMC LEADALL PACK SIEMENS |

3 1 1 2 2 1 1 |

|

3 |

Conveying control part: (1) Stainless steel structural framing (2) Convey roller table (3) Reducing motor (4) Opto-electrical controlling system (5) Controlling cabinet |

LEADALL PACK LEADALL PACK CHINA OMRON LEADALL PACK |

1 1 1 1 1 |

more details