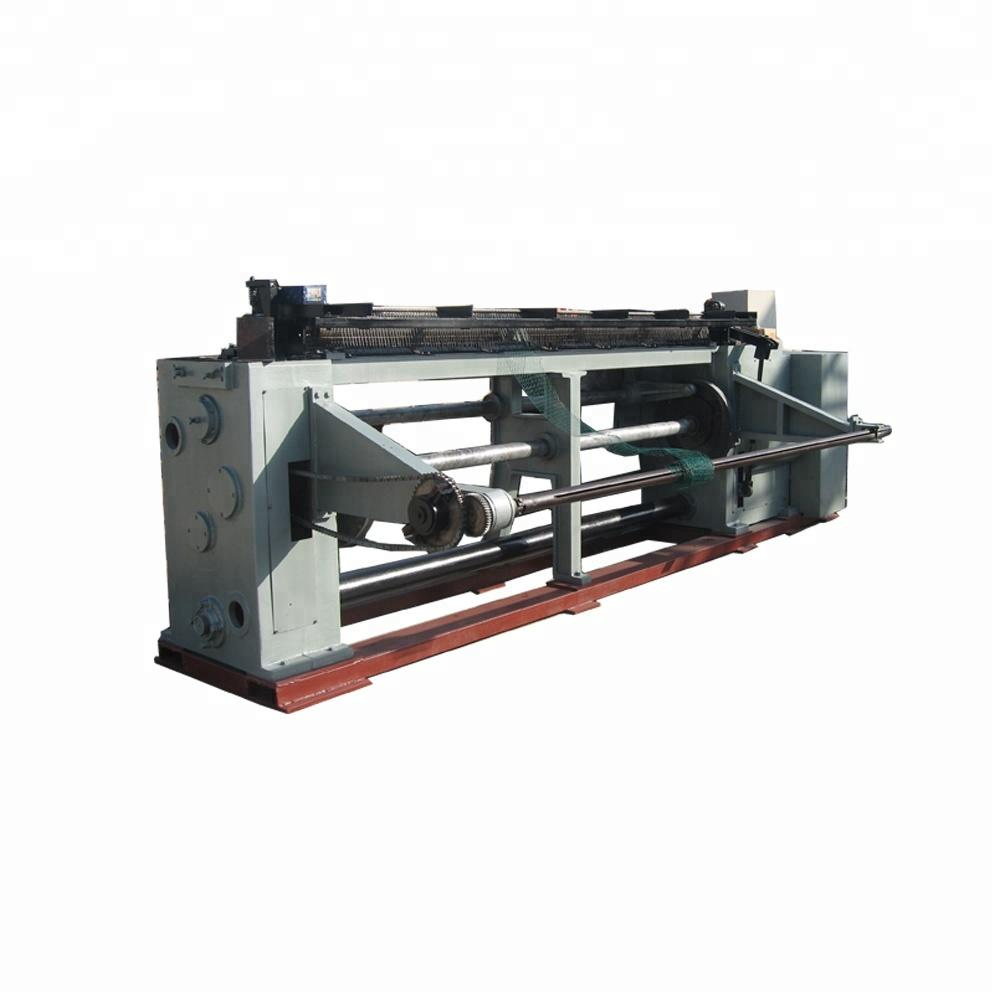

PLC Hexagonal wire mesh machine

Production Description

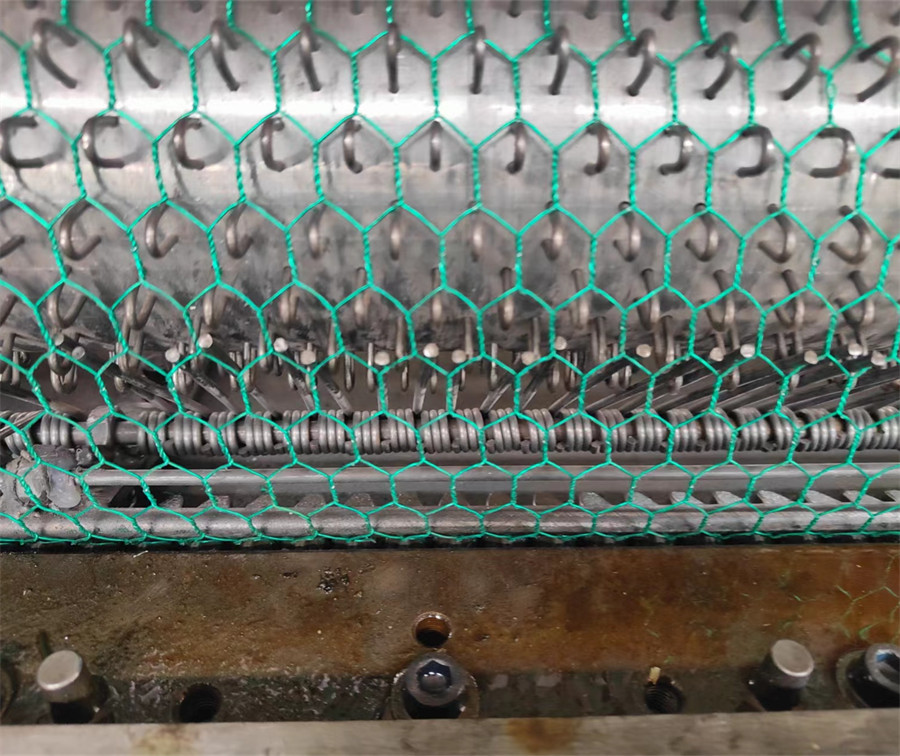

Low failure rate, simple maintenance, smooth operation and no noise. Machine production speeds are greatly increased, machines are more automated, more digital. The nets produced by this machine is often used in chicken nets, sheep nets, grassland nets, plateau nets, deer nets and etc. This is a new PLC Hexagonal wire mesh machine.

PLC Hexagonal wire mesh machine was developed by a group of mechanical engineers and electrical engineers in the industry. We use PLC servo control technology, high-precision mechanical accessories and high-precision servo motors, plus exquisite detailed design.

Machine parameters

|

Mesh Size |

Mesh width(mm) |

Wire Diameter(mm) |

Number of Twists |

Motor(KW) |

Working speed |

|

1/2" |

4000 |

0.38-0.7 |

6 |

7.5+4.4*3 |

60-80 mesh/minute |

|

3/4" |

0.4-0.7 |

||||

|

1" |

0.45-1.1 |

||||

|

1.2" |

0.5-1.2 |

||||

|

1.5" |

0.5-1.4 |

||||

|

2" |

0.5-1.6 |

||||

|

3" |

0.6-2.0 |

||||

|

4" |

1.0-2.0 |

||||

|

Can manufacture customized type |

|||||

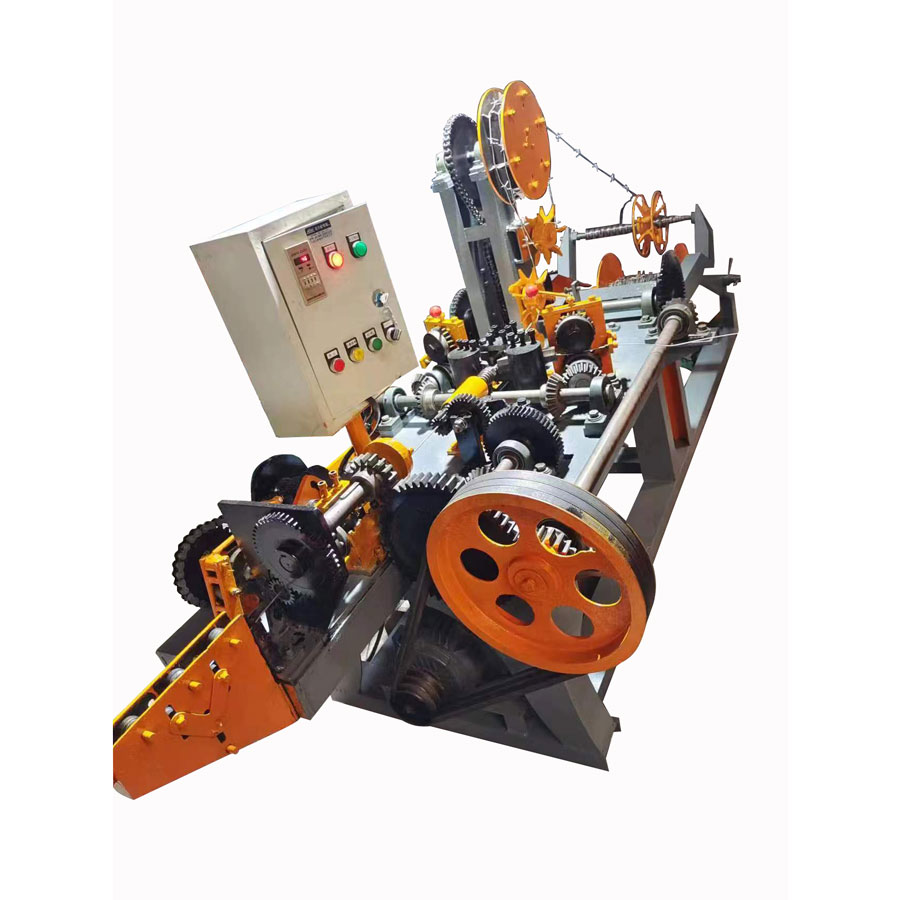

Advantages of PLC Hexagonal wire mesh machine

1.Low noise, high precision, high stability, convenient and fast operation.

2.Safe mechanical design.

3.Controlled by servo control system.

4.Delta servo control system has self-diagnosis function.

5.The data communication interface can be selected to connect to the control system, and an RS-485 communication interface can be equipped according to user needs.

Features

1.Very convenient for workers to operate.

2.More accurate, Less Wire and mesh broken. Once wire or mesh broken, alarm will reflect and machine will stop automatically.

3.Lubricating system makes the machine works more easily.

4.Speed more fast and production capacity improved more.