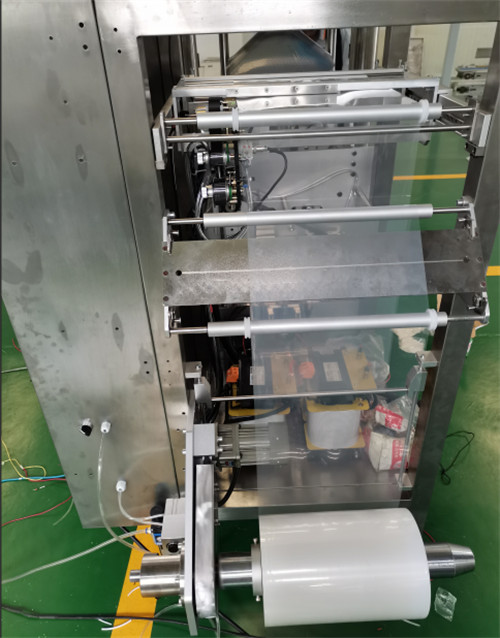

Powder vertical packaging machine

Applications

All kinds of powder materials like milk powder, wheat flour, coffee powder, fertilizer powder, other powdery product etc.

Main Technical Parameters

Model |

VFS7300 |

Filling volume |

1kg ~ 5kg per bag |

Capacity |

10 ~ 30 bags/min (It depends on the product feature finally) |

Bags size |

Bag length: 80---550mm, Total bag width: 80---350mm |

Film width |

220- 740mm (Change bag formers for different bag sizes) |

Film thickness |

0.04-0.12mm |

Weighing accuracy |

±0.2%~0.5% |

Bag type |

Pillowing bag, Gusseted bag (composite film/laminated film) |

Air consumption |

0.65Mpa, 0.6m3/min |

Power source |

1Phase 220V / 3 Phase 380V, 50~60Hz, 5.5Kw |

Dimension |

L2880 x W1820x H3530mm |

Machine Weight |

1500kg |

Packing Materials

BOPP / Polyethylene, Aluminium foil / Polyethylene, Paper / Polyethylene, Polester / Plated aluminium /Polyethylene, Nylon/CPP etc.

Safety and Hygiene

No film, the machine will alarm.

Machine alarm and stop when the inadequate air pressure.

Safety guards with safety-switches, machine alarm and stop when the safety guards are opened.

Hygienic construction, the product contact parts are adopted sus304 stainless steel.

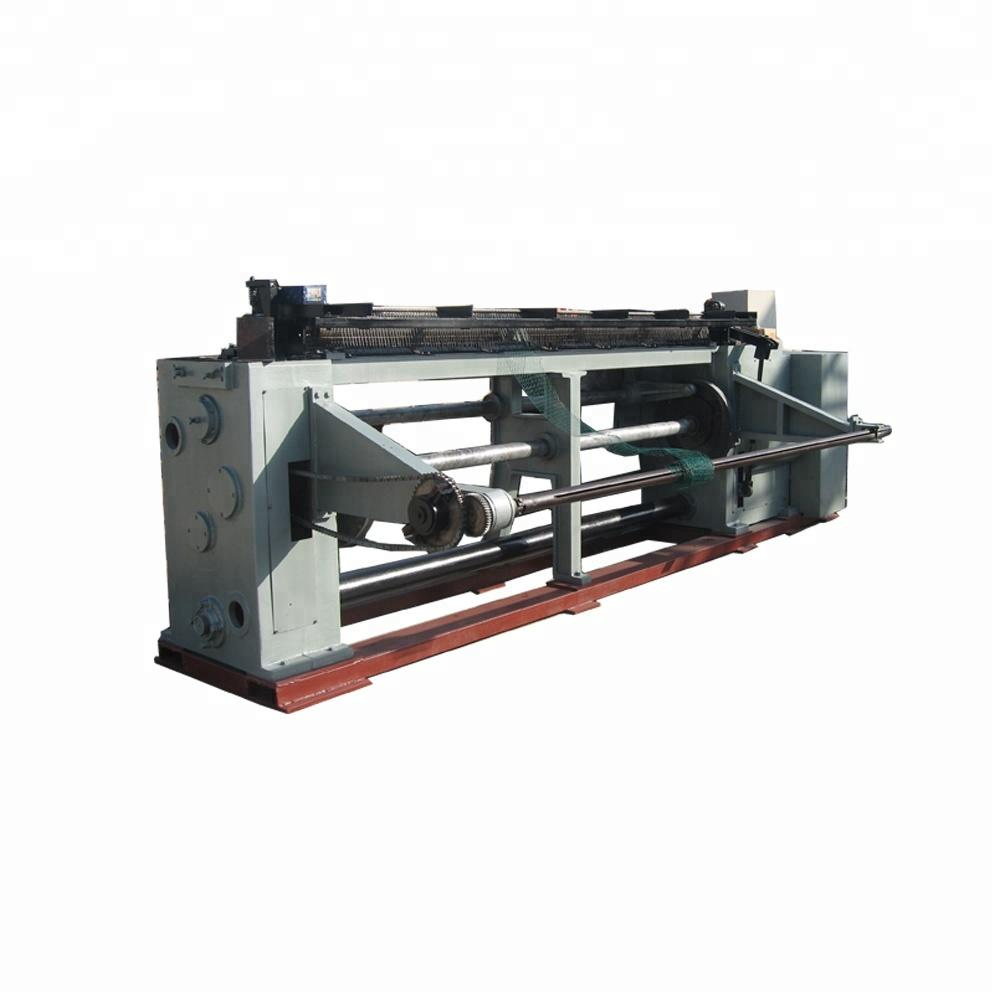

Whole System

The functions included automatic feeding, weighing, packaging, sealing, and printing, counting and finished product conveying. It adopts PLC control apparatuses which are imported from well-known international companies. Thus, they are of reliable performance. The finished products done by automatic vertical packing machine are of magnificent appearances.

Your package unit will be consist of Vertical Roll Film Packing Machine, Servo Auger Filler, Screw Elevator, Finished Bags Conveyor, Electric control cabinet. These all comes together that is guaranteed to put a neat finish on the packing.

Items List

|

No. |

Product Name & Description |

QTY |

Photos |

||||||||||||||||||||||

|

1 |

Vertical Roll Film Packing Machine (including: one bag making former for 1kg bag, ribbon printer) Features:

|

1set |

|

||||||||||||||||||||||

|

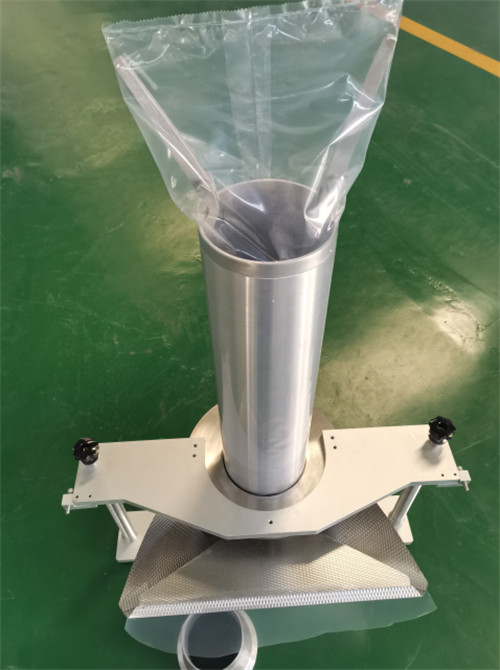

2 |

Bag Making Former (for making 2kg bag) |

1set |

|

||||||||||||||||||||||

|

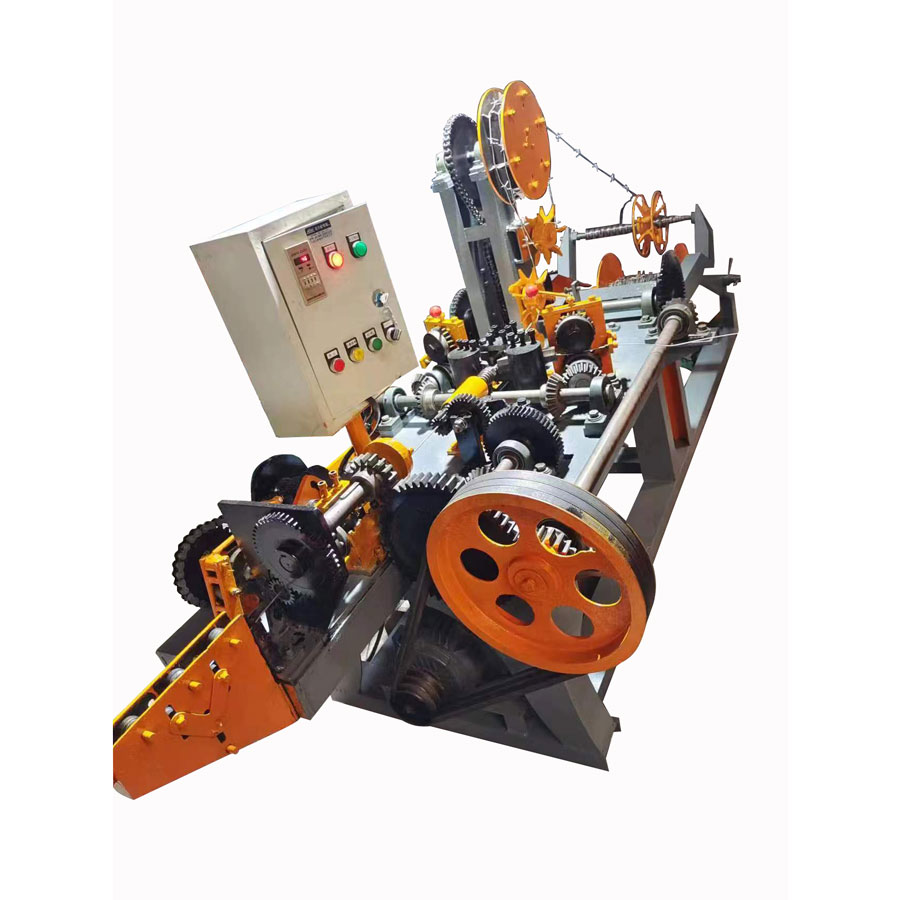

3 |

Servo Auger Filler (for weighing 100g~2000g powder) Technical parameter:

|

1set |

|

||||||||||||||||||||||

|

4 |

Screw Elevator (for feeding powder) Application:Screw conveyor is developed for conveying powder product, such as milk powder, rice powder, gourmet powder, amylaceum powder, washing powder, spices, etc. Features:This machine adopt screw conveying material, and the storage can be vibrated. it is suitable for conveying various powder and little pellets Technical specification:

|

1set |

|

||||||||||||||||||||||

|

5 |

Finished Bags Conveyor The machine can send the packed finished bag to after-package detecting device or packing platform. Technical specification:

|

1set |

|

Our Services

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintenance and replacement service;

8. whole process training and guidance from our technicians. High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.