25kg Bagging Machina, Implens Infundibulum Pera 25kg PVC Magister batch, EVA Magister batch, Polymer Magister batch

General Technical Specification

| Nomen | 50 Kg abs resina sarcina Machina, 25kg abs resina machinula flling, Automated Bagging Line, Bag Packing MachinePrice,abs polymer Packaging Machina, 50 Kg Bagging Machina, Automated Bag Packaging Machinery, abs resina, abs resina materia, abs materia plastica, abs pc materia" , abs polymer, abs materia plastica, resina plastica, epoxy resinae absplasticae, resinae technicae machinae sarcinae, apparatus abs resina sarcina, 25kg Sacculum implens Machina, 25kg kraft charta bagbagging apparatus, 25kg masterbatch bagging machine |

| Bagging range pondus | 10-25kg |

| Celeritas stipare | ≤300bags / hora |

| sacculum dimensionis | width:400- 520mm; longitudo: 550-950mm |

| Aeris consummatio | 1Mpa |

| Gas consummatio | 3m³/min |

| Potentia voltage | 220/380VAC tria pascha, 50HZ |

| Potestas | 5Kw |

Application & Pera Sample

Materia granula: abs resina. abs resina materia, abs materia plastica, abs PC materia, abs polymer, abs plastic, resina plastica, epoxy resina absplastic.PE masterbatch. PP masterbatch, ABS masterbatch. PVC masterbatch. Eva masterbatch. polymer masterbatch. plastic masterbatch polyolefin masterbatch, masterbatch, thermoplastic polyester elastomer, polyester rubber, TPE, TPY, TPR, TPO, TPU, TPE etc.

Sacculi Type: Kraft Bag, PP pera texta, PE sacculum etc

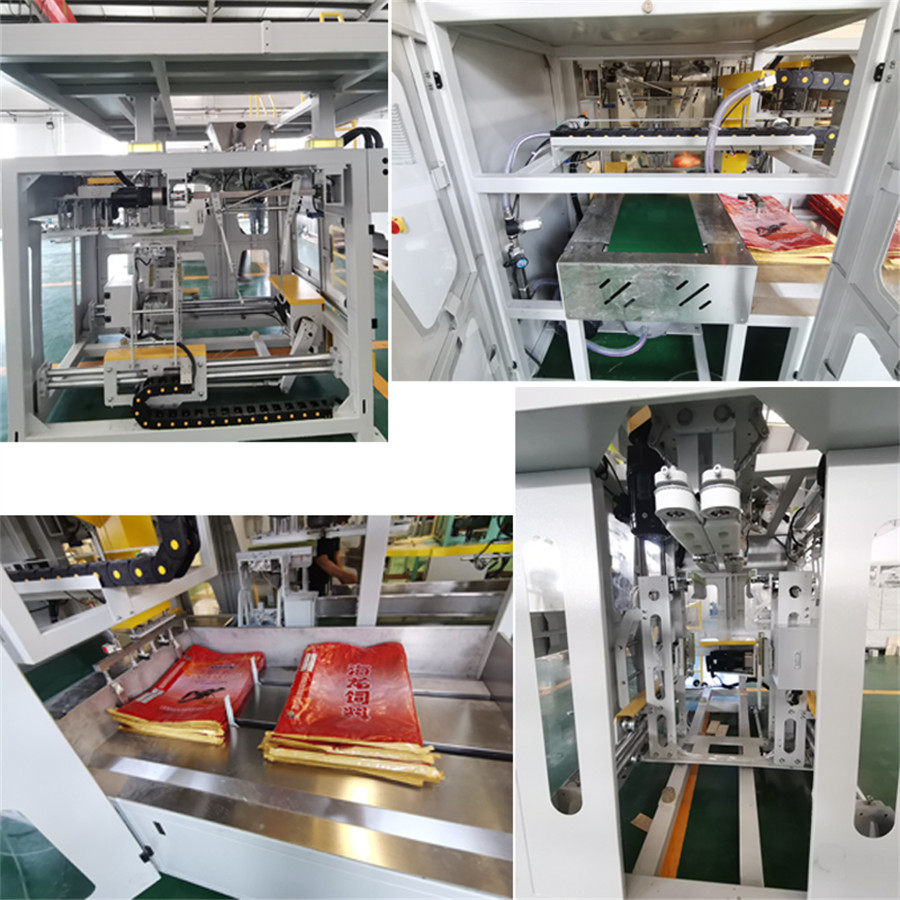

Processus working

1. Pre-packed inanis Sacculi

Pone 2-3 acervos inanis saccis simul ad praebendum saccos ad machinam packaging.

2.Take inanis pera

Tergum mechanismum sugens fundum sugit pera cum negativa pressura. dum princeps-typus sacculi transmissionis structuram dorsum os adulat et ad sacculi stationem aperiendam transmittit.

3.Open sacculum inane

Sacculi aperiens mechanismum simul positivas et negativas latera sacculi os pressionis negativae sugit. Negatio pressionis sacculum os sugit et elevat, ac deinde structura cultri "inserta" in utraque parte emissionis materialis portum in bigmouth emissae rotationis inseritur et ad utrumque latus diffunditur.

4.Supply vacua sacculi

vacuum transferre sacculum ad sacculum clamping mechanismum levando bracchium cultrum ad perficiendam malam operationem praestandam. Dorsum clamping mechanism fibulatis sacculi utrinque ne pulvis exuberet

5.Material Implens Deprehensio sacculi clamping fabrica fidem efficit supplendi sacculi. postquam gestum est. PLC signum erit ponderis activitatis automatice unitatis tunc materia in pensatione unitatis in sacculum sarcinarium solvetur. Per fueling processum, vibrationis vibrationis bullam facient operation. Eodem tempore. per externi pulveris remotionem interface. pulvis qui formatus est exantlaretur in processu dimissionis

6.Holding sacculum et sutura sutura & æstus signavit

Post materiam ingeris absolvitur. Sacculi os horizontaliter per sacculum portans mechanismum coagmentatur. deinde saccus transversae ad mechanismum extra introitum defertur. et dorsum deferatur ad secundum stationem signandi caloris ad suturam latae suturae seu caloris signandam.

Product Characteres

1. Securus operari et usus

2. Apparatus sacci fibulatorum promovetur, materia automatice impleri potest 3) Imple materialia ratio habet apparatum materialem stop, accurationem altum imperium, partes operis omnes usus partes importatas, stabilis et certas cum machina sutura

3. Caloris apparatus signandi ad libitum.

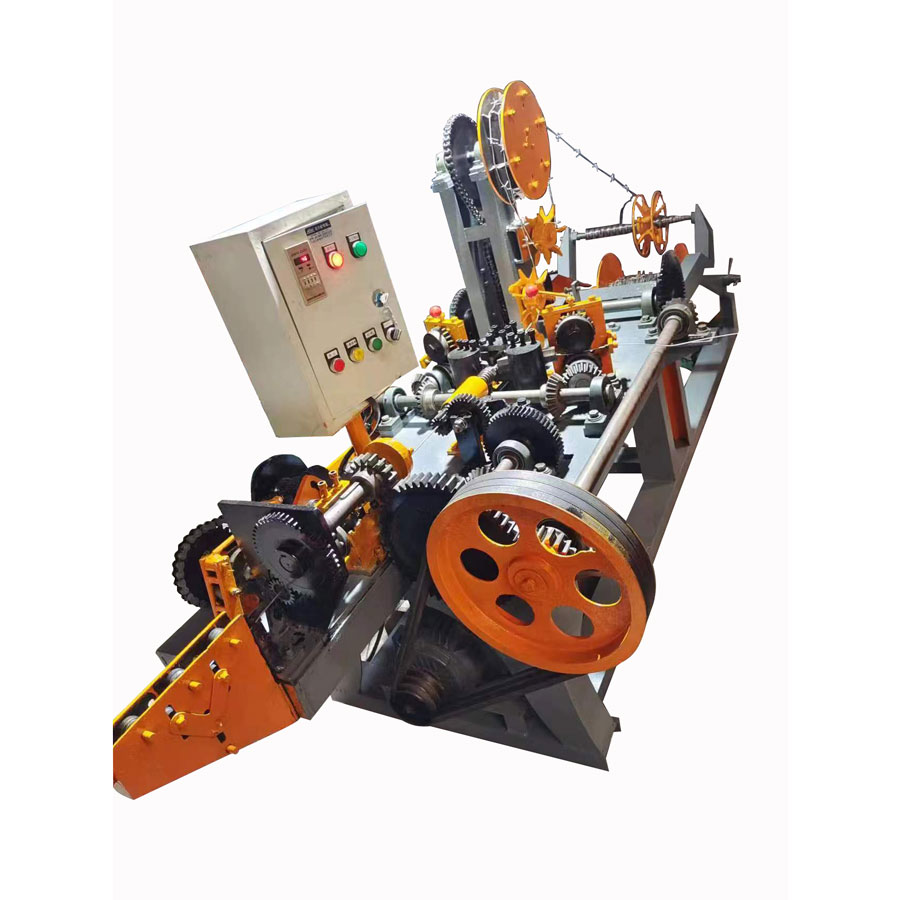

GFCK-G Mole Granular Materials Bagging Machina

Max Volo: CM Sacculi / H

Optiones

- Plena machina ferro stainiess

- Pulvis Dollector

- Pascentium eevato

- sacculum iabeling

- CIJ printer

- Robotic paltetizing system

Features

- Omnis operatio

- Shurdy constructione

- Foedus design

- princeps rliably

Applicationem

GFCK-G est machina capacissima plene latae cum productione capacitatis usque ad 750 saccos per horas, specimen pro aufomatic sarcina materiarum granularium cum bono fludty, ex 25-50kg latitudinem ponderans.

Haec machina idealis omnibus illis qui ab manualsem-aulomatico bagging movere volunt ad capacitatem latae capacitatis plene et/vel requirendam humilis capacitatem. eius compacta magnitudo permittit machinam in quavis area productionis exsistente positam.

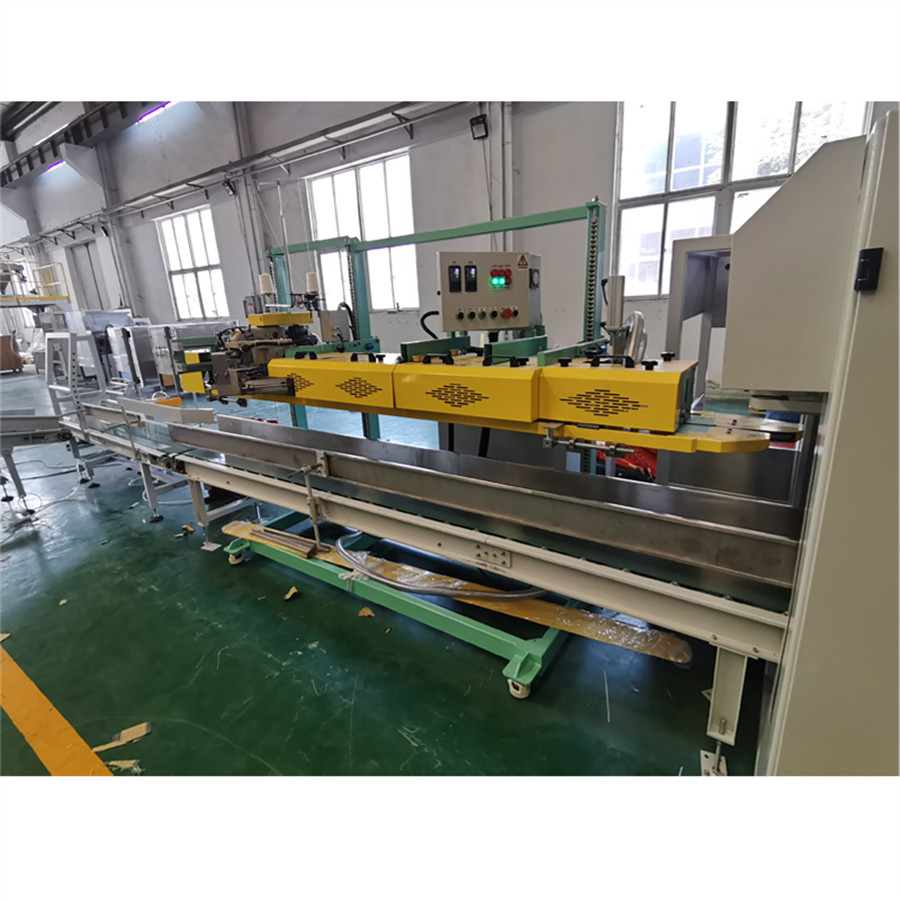

Technical parametri

Sectio |

Items |

Specification |

Mechanica notitia |

Apparatus dimensio (L*W*H) |

3090* 2735* 2300mm (agmen) |

Apparatus pondus |

4800kg |

|

Machina materia |

Contactus partes SS304 * Carbon ferro compages |

|

sacculi magnitudine |

580* 1000 (can be customized) |

|

Genus sacculi |

Planum apertum os bag.M-gusset bag |

|

Sacculum materiale |

PE.PP Texta, Kraft sacculi |

|

Ambiens temp. |

-10℃~35℃ |

|

IP gradus |

IP56 |

|

Electrical data |

Potentia copia |

AC380V±10% |

Frequentia |

50/60Hz |

|

Virtus consolutio |

15kW |

|

Cogo aere |

0.5~0.7Mpa |

|

Aeris consummatio |

≤1200L/min |

|

Euismod date |

Celeritas stipare |

> DCC (25kg / pera plastic granula, singula servo scale, plana sacculi) |

accurate perpendens |

0.20% |

Home

Home